I-75 Power Line Shutdown – A Planned Grid Operation

Ever notice those tall power lines following the highway on your drive? Sometimes, they need to be completely shut down. The I-75 Power Line Shutdown refers to a significant, planned operation where utility companies deliberately de-energize high-voltage transmission lines along this major interstate corridor. This isn’t a random outage; it’s a carefully orchestrated event for maintenance, safety, or upgrades. This article breaks down why these shutdowns happen, how they’re managed, what gets fixed, and the immediate effects on the grid and community. We’ll look at the operational reasons, the complex logistics, the technical work involved, and the direct consequences of taking such critical infrastructure offline.

Operational Rationale for the Shutdown

Think of the electrical grid like the circulatory system for our modern world. The high-voltage transmission lines along I-75 are its major arteries. Just as arteries need check-ups and repairs, so do these power lines. A planned I-75 Power Line Shutdown is almost always a proactive measure. It’s a controlled pause to prevent a much larger, uncontrolled failure that could leave people in the dark for much longer.

So, what specific factors necessitate this action? The reasons are usually practical and safety-driven. First, age and wear are big factors. Equipment like insulators, connectors, and the wires themselves degrade over decades of exposure to sun, ice, and wind. Utility crews need to physically inspect and replace these components to prevent a future breakdown. Second, severe weather damage from a past storm might require major reconstruction of towers or lines. Third, it could be for an upgrade. As energy needs grow, companies might need to install newer, higher-capacity wires or add equipment to make the grid smarter and more resilient.

Ultimately, the decision boils down to a simple trade-off: a short, planned inconvenience is far better than a long, unexpected emergency. Utility companies analyze reams of data on equipment health and forecast weather to choose the least disruptive time for this essential work. They’re balancing the immediate hassle of a shutdown against the long-term goal of keeping the lights on reliably for everyone.

Logistical Execution and Public Coordination

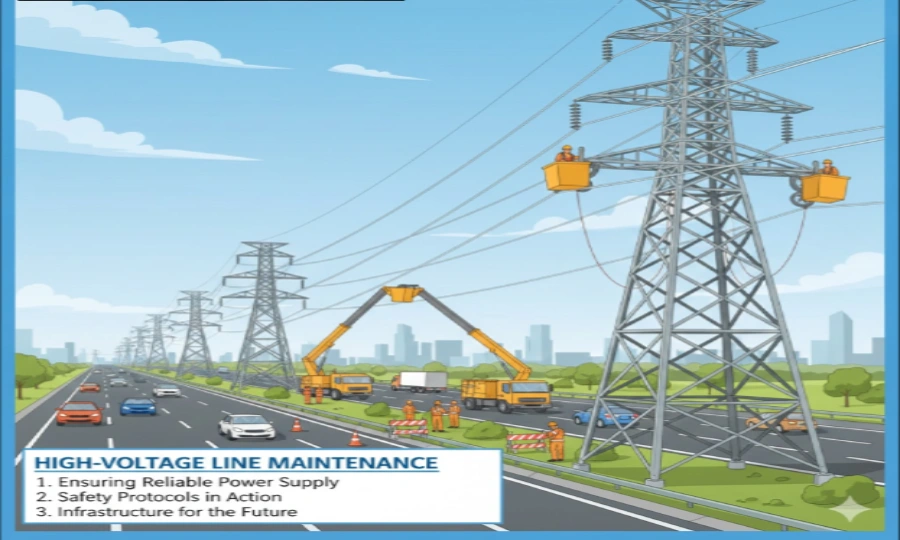

Pulling off a major power line shutdown is a massive coordination feat. It’s not just about flipping a switch. Multiple agencies and thousands of people need to be on the same page. The planning for such an event often starts months, if not a year, in advance. Engineers design the work, safety officers plan every crew movement, and logistics teams get all the parts and giant equipment—like bucket trucks and cranes—in place.

How were the shutdown and public notifications managed? Communication is key. Long before the power goes off, the utility company works with state departments of transportation (like MDOT in Michigan or GDOT in Georgia, depending on the I-75 segment) and local city governments. They send out press releases, post detailed maps on their websites, and use social media to alert customers. Important customers, like hospitals, large factories, and water treatment plants, get direct phone calls. Often, you can find an outage map on the utility’s website showing exactly which neighborhoods will be affected and for how long.

And it’s not just about electricity. If the work is right next to the interstate, it involves traffic control too. Crews might need to close a lane or a shoulder to operate their cranes safely. This requires more permits and coordination with highway patrol to ensure driver and worker safety. Every minute of the shutdown is scheduled, from the safety briefing at dawn to the moment they request to re-energize the line. It’s a tightly choreographed dance to get the work done as quickly and safely as possible.

Technical Scope and Affected Infrastructure

The scale of work during an I-75 Power Line Shutdown is impressive. It’s not just a single pole; it can span miles of heavy-duty infrastructure. The “technical scope” refers to all the physical assets and geographic area involved. Let’s break down what typically gets taken offline and worked on.

First, the circuit itself. A transmission circuit can run for 50 to 100 miles or more. The shutdown might affect the entire circuit or just a critical segment of it. This involves the steel lattice towers or large wooden poles, the thick aluminum power lines (called conductors), and the glass or porcelain discs (insulators) that hold them up. Second, substations are involved. These are the fenced-in facilities you see near the highway where voltage is stepped down. The shutdown will affect the specific substations where the circuit begins and ends, requiring work on switches, breakers, and transformers.

Here’s a simplified look at the typical scope:

| Component | Description / Typical Scope |

|---|---|

| Circuit Length | A segment of high-voltage (often 138kV or 345kV) transmission line paralleling I-75, potentially spanning multiple counties. |

| Affected Area | The specific towns, suburbs, and rural customers whose electricity comes directly from the de-energized circuit. |

| Utility Assets | Dozens of transmission towers, several substation connections, and all associated wires and insulators in the work zone. |

| Interstate Coordination | Possible lane closures or slow-downs where the work zone intersects with or is adjacent to I-75 right-of-way. |

The goal during this phase is physical work: crews in buckets carefully replace worn parts, helicopters might string new wire between towers, and inspectors use drones or special cameras to get a close look at hard-to-reach spots. It’s hands-on, high-stakes work that can only happen when the line is completely dead.

Immediate Operational Consequences

When the shutdown happens, the grid doesn’t just go dark in one big area. Modern grids are built with backups and alternate paths. One of the first operational consequences is what grid operators call “re-routing.” Control room engineers work to shift the electrical load from the downed line to other nearby transmission lines, if the system’s capacity allows it. This isn’t always possible for the entire affected area, which is why some planned outages are unavoidable.

For customers on the affected circuit, the consequence is a planned, communicated power outage. This means no electricity for homes, businesses, and traffic lights in that specific zone. Businesses might close or run on generators, residents need to plan for food spoilage, and everyone has to reset their digital clocks when it’s over. It’s a direct, temporary disruption to daily life in exchange for long-term reliability. For essential services, this is when their backup generators automatically kick on to keep critical operations running.

Furthermore, there are consequences for the workers and the highway. If the work is adjacent to I-75, drivers will see cones, reduced speed limits, and maybe a lane closure. Large “utility work ahead” signs warn of the activity. The consequence here is minor traffic slowdowns for the safety of the crews working just off the pavement. Finally, once the work is done, the process isn’t over. Restoring power is a careful, step-by-step process to ensure everything is reconnected correctly before the circuit is re-energized and brought back online to serve its customers once again.

Conclusion

In the end, the I-75 Power Line Shutdown is a textbook example of necessary maintenance. It’s a complex, highly planned operation that prioritizes long-term safety and reliability over short-term convenience. From the engineers who plan it to the lineworkers who execute the dangerous repairs, the entire process is designed to minimize disruption while maximizing the health of our shared electrical infrastructure. While the temporary outage is a hassle, it’s a clear sign that the utility is actively working to prevent the kind of large-scale, catastrophic failures that cause much longer blackouts. Understanding this process helps us see the controlled shutdown not as an inconvenience, but as a sign of a system being proactively cared for.